Supply chain: what it is and its characteristics

The supply chain is a process that indirectly and fully affects our day-to-day.

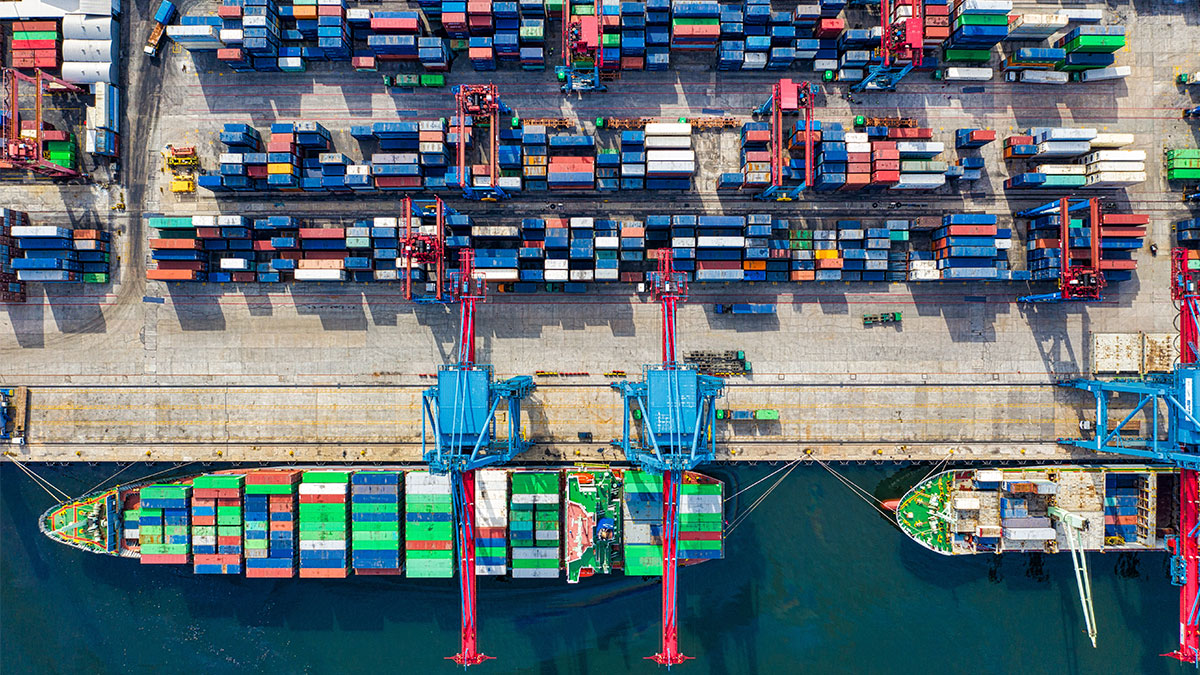

In every purchase that we make, in the transport of goods, in the warehouses of online retail giants… the supply chain is a set of activities, a cross-cutting and global concept.

Supply Chain: Definition

The supply chain is a strategic and logistics function that involves all operations that are vital for ensuring that a product or good reaches the end customer.

Put another way, it is the complete life cycle of a product: from its raw material state to its final sale. It covers the supply of raw materials for the manufacture of a product through to its delivery to the end customer. The supply chain therefore involves the supply, production, storage and distribution processes, and requires coordination between every link in the chain.

It is a complex process, due in large part to globalisation which has blurred commercial boundaries, thus involving more active parties in the process, more competition and more stringent demand requirements. Added to this is the unstoppable rise and omnipresence of ecommerce, which has broken down all geographical and time barriers, and which has also come to the fore during the pandemic with the change in many consumer habits.

Supply Chain Phases

Planning is the first phase required in any industrial activity. How something is going to be manufactured, where it is going to be manufactured or what processes and tools are going to be used must be previously defined.

Depending on the type of product, it will be necessary to find adequate storage facilities and conditions, containers and packaging to be used, safety measures, manufacturing processes, quality testing, etc.

A detailed planning of elements related to the supply chain is the best way for it to work optimally in terms of speed and efficiency. As in any industrial activity, aspects such as the place of manufacture, human and material resources needed, storage facilities and conditions, quality standards and regulations to meet etc., must all be considered.

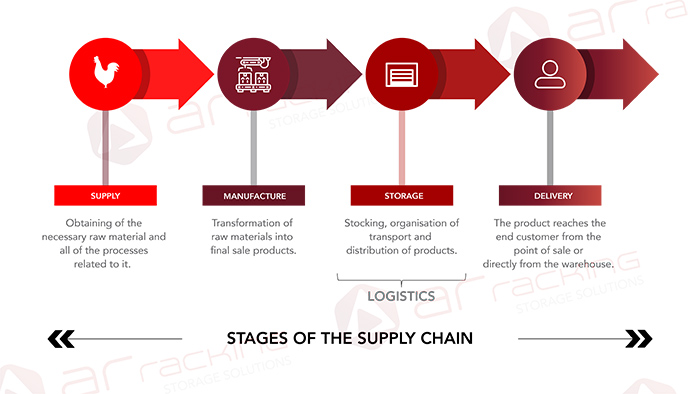

Having passed phase 0 or the prior strategic definition phase, 4 major stages in the supply chain can be identified.

1. Supply:

This phase is focused on the activities required for obtaining the raw materials and subproducts necessary for the manufacture of the products to be sold. In this stage of the supply chain, it is important to have the availability and quantity of materials and their timescales well planned and coordinated.

2. Manufacture/production:

This phase includes all processes related to the creation and preparation of the product. That is to say, the operations necessary for the transformation of raw materials into products and their mass production. Optimisation of the industrial process plays a key role in the standardisation of operations and therefore in a more agile and effective cycle.

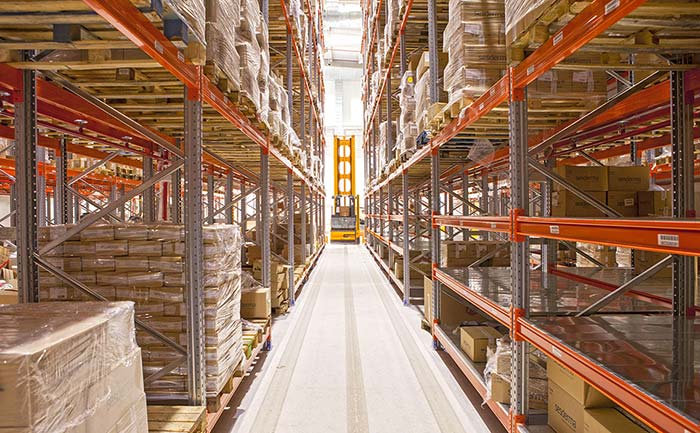

3. Storage:

The central phase of the supply chain, storage, consists of the temporary handling of goods and their quality and quantity control in a particular space so that their inflow and outflow is profitable for the company. In this phase, many factors come into play that can mark the difference between the efficient management of a company’s supply chain and activity and the business steering off course. Warehouses and/or distribution centres are the focal point of this stage.

Correct management will anticipate any production peaks or fluctuations in demand and their effect on stock and its management. At the same time, storage management will take into account the storage and provision costs to avoid any increase in price of the product or final service, ensuring an optimum response to varying levels of demand and maintaining inventories at the levels required by the business. For this, the choice of the type of industrial racking to install in the warehouse will be key.

4. Distribution and delivery:

Let’s look at the final stage of the supply chain, when the product reaches the end customer. This covers the product leaving the warehouse and distribution centre through to its delivery to the end customer. The objective, apart from making the delivery to the final destination, should be that the product reaches the customer in good condition and within the agreed deadlines.

Although the closing phase of the supply chain cycle is the distribution and delivery phase, another stage could be included too. This is the returns stage, in which a reverse process is initiated where the end customer sends the product back to the company. The rise of ecommerce in recent years has forced supply chains to change.

Supply chain characteristics

The main objective of the supply chain is to deliver articles or products in the quantity, quality and time necessary at the most competitive cost during the whole process, from the supply stage to final delivery. For this, the supply chain must include certain characteristics:

- Balance: a supply chain is a succession of coordinated activities which together acquire certain complexity. The complete cycle involves many human and material resources. So that the entire process is successfully completed, all parties involved must operate correctly. It is therefore important that each phase or stage is well planned, detailed and simplified to minimise potential risks.

- Efficiency: reducing costs and executing the phases appropriately at the same time is a characteristic of a well-functioning supply chain.

- Coordination: suppliers, transport, manufacturers, customers, technology… make up the supply chain. They must work independently but in an organised way so that the product reaches the end customer satisfactorily.

- Flexible: an efficient supply chain is agile and responds rapidly to changing market patterns or global incidents that arise, such a health crisis. That is to say, responding effectively to changes in supply and demand.

- Transparency: that there is a continuous flow of information throughout the process, from supply through to final delivery. A supply chain that works well is a supply chain with dynamic communication.

Supply chain and logistics management: are they the same?

The answer is no. Logistics is another link in the supply chain. Logistics refers to activities related to the efficient management of the storage of products/goods, the organisation and execution of transport, and distribution to the end customer.

It can be said that while the objective of logistics is to manage the order optimally, the objective of the supply chain is the comprehensive and global management of a product from its primary origin until it reaches the hands of the final recipient. The supply chain integrates more operations, apart from logistics, such as supply, manufacture and other types of activities related to the sales or marketing areas.

Source : ar-racking.com