Electric Cars With Recycled Batteries Are the Next Green Holy Grail

The seven men are traders of a hot new commodity in the world’s biggest and most mature electric-vehicle market: used batteries. Each one contains prized ingredients like lithium, cobalt and nickel that can be extracted and resold. With millions of EVs now ready to be discarded, and thousands already abandoned in graveyards across the nation, there’s a flood of retired batteries waiting to be recycled.

The seven men are traders of a hot new commodity in the world’s biggest and most mature electric-vehicle market: used batteries. Each one contains prized ingredients like lithium, cobalt and nickel that can be extracted and resold. With millions of EVs now ready to be discarded, and thousands already abandoned in graveyards across the nation, there’s a flood of retired batteries waiting to be recycled.

All those precious metals, hidden in junkyards, parking lots and driveways across China, are a crucial resource as global competition for critical minerals escalates and countries jostle to come out on top in the green transition. An effective, safe and environmentally friendly system for collecting and processing batteries would put Chinese carmakers ahead of the curve. They’d be able to produce electric cars with recycled batteries at scale — making them doubly green — giving them an edge over international rivals as governments mandate more EV sales and places like Europe require minimum levels of recycled metals in vehicles.

Reaching that point however will require consolidating a sprawling industry of thousands players — from freelancers like Li and other small unofficial recycling workshops to giant battery makers. Li, 29, is part of a gray market that’s emerged alongside a fast-growing battery recycling industry seeking to profit from China’s first wave of EV decommissioning. He asked to only use his last name because he operates outside of the government system set up for processing used batteries.

Policy makers are starting to put regulations in place but, right now, there’s still plenty of money to be made beyond the confines of official rules. “It’s just like a wild fish pond without anybody taking care of it,” Li said. “Whoever knows where the pond is gets the fish.”

Recycling has always been a chaotic business. From plastics to fast fashion, collecting, transporting and processing waste requires coordination between multiple companies that aren’t always incentivized to work together.

The same issues plague China, where one in every three new vehicles sold is electric, compared with one in eight in Europe. Officials say the nation may reach its goal of having electric cars account for 50% of all new sales by 2026 — 10 years ahead of schedule. According to the consultancy Circular Energy Storage, China will have nearly four times as many batteries to recycle by 2030 than it did in 2021 and the nation dominates when it comes to preprocessing and materials recovery. Some market research suggests an EV battery could last around five to eight years, although some say longer.

But China’s battery recycling regulation is still nascent. It’s sometimes convoluted for battery manufacturers and automakers to retrieve expired cells, many car owners don’t know they can get paid for their used batteries, and recycling companies have struggled to secure a reliable stream of old ones.

That’s where traders like Li step in. The 29-year-old posts advertisements on social media platforms such as Douyin, a TikTok-like video platform, and leverages friends and family to find potential sellers. A battery could show up in a faraway province, so he’ll sometimes arrange for a courier from a ride-hailing service to pick it up, or travel to another city himself.

From there, the battery could go to a middleman, an unlicensed workshop to be broken down, or to an official recycler. Transactions are always done quickly and in cash because raw material prices are so volatile that recycling rates can change in as little as half a day.

Yang Lin, secretary general of the battery recycling committee set up under China’s Electronic Energy Saving Technology Association, estimates that unregulated operators currently make up about a fifth of the market. With the cost of setting up just one recycling processing line running to around $15 million, it’s easy to see why bit players have sprung up. Their presence threatens to undermine the credibility of China’s recycled batteries because they don’t always adhere to environmental and safety standards. And because they don’t have to invest in those proper protections, they can offer EV and other battery owners higher prices, diverting valuable cells to a less desirable supply chain.

“Once you allow more of these small workshops to exist, the resources will flow to wherever they can generate the highest return,” says Zhang Yuping, deputy general manager of one of the nation’s biggest recycling companies GEM Co. “It’s just like drugs.”

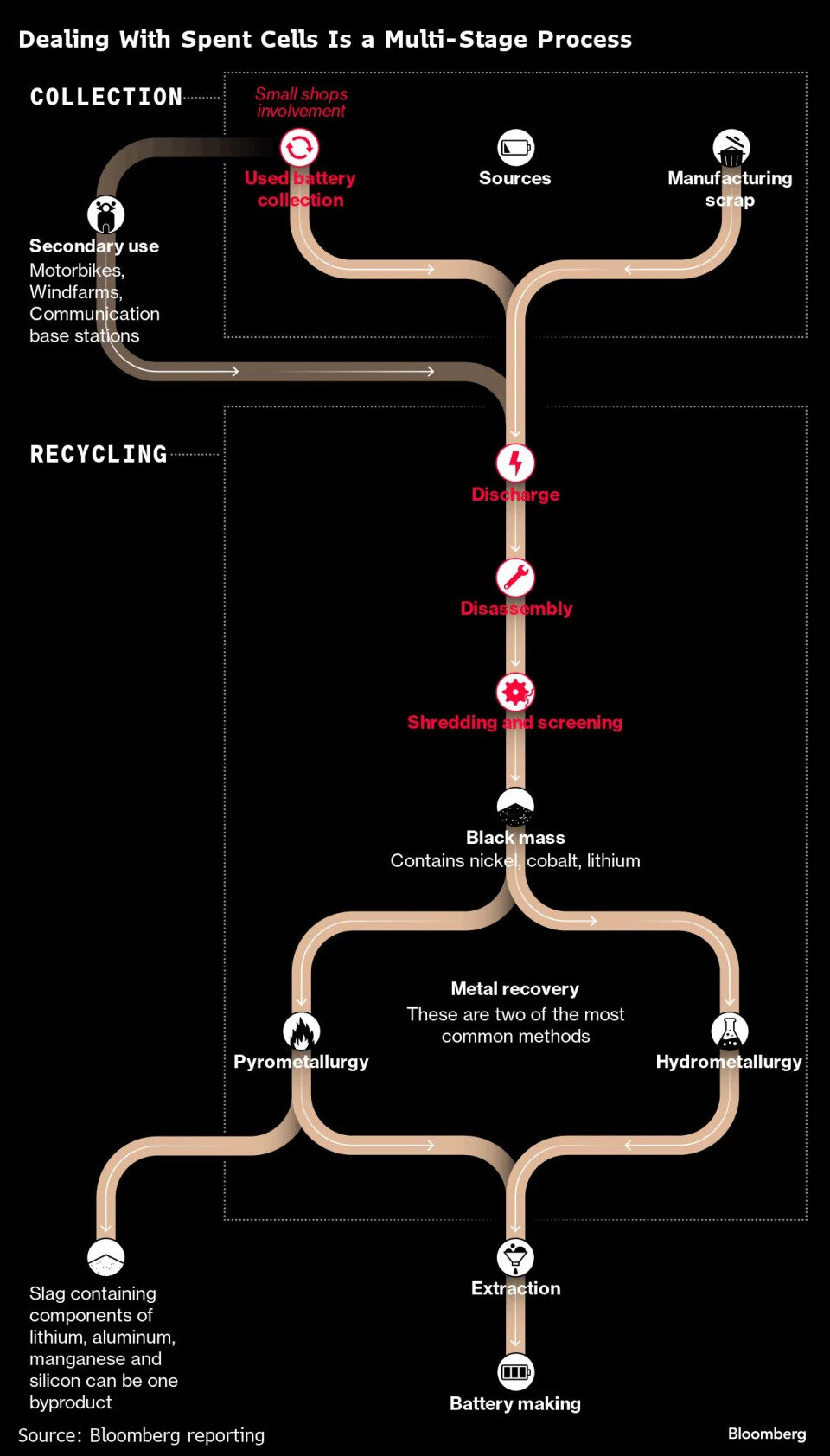

The most profitable EV batteries to recycle are made of lithium, nickel, cobalt and manganese. To extract the metals, the batteries have to be dismantled and shredded into what’s known as “black mass,” which is then dissolved in powerful chemicals.

It’s that first step that’s sparked a cottage industry of small-time recyclers in places like Tangxia, a town near the southern Chinese city of Dongguan. Xu Wei, one battery broker Bloomberg spoke to there, said business was thriving until the local government cracked down following a series of accidental fires.

Pan Juntian, a reporter at a local media outlet, spent two weeks undercover to get a look inside these workshops. “Without advanced machinery, the dissembling of battery packs requires a huge amount of labor,” he said. Workers paid by the hour, with just cloth masks for protection, used wrecking bars and electric saws to pry open the boxes. They were “all male, and it took them at least one hour to open up a battery pack.”

The conditions are a far cry from GEM’s state-of-the-art research and development facility in Wuhan. Cameras equipped with thermal sensors monitor for potential fires as workers use forklifts — powered by recycled batteries — to sort and transport used batteries into warehouses. Special cabinets help to control the voltage and current to prevent explosions during the initial processing stages.

At another GEM facility that Bloomberg visited in Jingmen, a multi-story system of conveyor belts, pipes, furnaces and crushers exemplifies the semi-automated processes adopted by major players in China. Workers in gray jumpers and hard hats wore heavy-duty industrial masks to protect their lungs from the dust.

GEM, which says it processes around 10% of China’s retired EV batteries, quadrupled its recycling revenue last year from 2021. It also earned a spot on the government’s so-called whitelist of 156 key industry players, which grants companies priority status when bidding for key government and state-owned enterprise projects. Gaining entry requires passing rigorous evaluations that cover operations as well as environmental and technological standards.

None of that applies to the gray market fueled by traders like Li and workshops like the ones in Dongguan. It’s a big safety risk because they’re dealing with things they don’t fully understand, said an analyst at a commodity-pricing firm, who asked not to be named discussing unofficial activities.

Transportation is another problem. Under China’s national standard, trucks carrying old batteries must be equipped with smoke alarms as well as flame retardant and heat-insulating packaging. But many unofficial players either don’t want to pay the cost, or don’t have the resources.Instead of using specialized vehicles, some turn to Huolala, an on-demand trucking service provider, said Yu Haijun, vice president of Guangdong Brunp Recycling Technology Co., a subsidiary of Chinese battery giant CATL. “The transport from point A to point B could cost 40,000 yuan or 4,000 yuan. The difference is huge.”

The Chinese government has been trying to regulate the quick-growing market.

An overarching policy framework is in place to offer guidelines about the responsibilities of the various players. There are national standards on battery specifications and around the dismantling of cells and their remaining power-testing requirements. Beijing is also pushing for a country-wide platform to track the lifecycles of batteries.

But industry watchers say the measures currently lack enforcement power.

The government directs automakers and others to work with recyclers on the whitelist, “but technically that isn’t compulsory right now,” said Yang Qingyu, a senior consultant with the China Battery Cooperation Union, a nonprofit organization that includes more than 2,000 companies.

As a result, and in the absence of severe penalties, the reality is that many retired batteries still flow into gray-market channels. Stricter rules that inflict punishment on non-compliant players are needed in order to foster a healthier market. GEM’s Zhang, for example, says the whitelist should become “not only a recommendation list or a priority list, but a real entry qualification” by 2025.

Cleaning up its recycling act even further would help China cement its world-leading position in the EV market. Automakers would lower costs if they recycled the batteries in their cars, says Hu Feng, vice president of the Shenzhen-based GaoGong Lithium Battery Research Center. Over time, they would build a stable supply of core materials.

Its ESG credentials would be burnished also. The carbon footprint of recycled EV materials is lower than from traditional mines. In the case of a nickel-rich battery in Europe using the hydrometallurgical method, for example, the carbon footprint could be four to five times less, according to McKinsey & Co.

Every gram counts when prices of electric-car raw materials have surged to historic highs over the past year. China still relies on overseas imports for more than 90% of its cobalt and nickel resources, and more than half of its lithium. Industry guidelines dictate that each recycled battery should yield at least 98% of its original cobalt and nickel content, and 85% of its lithium. Big recyclers have no issues reaching the thresholds, but smaller players can struggle.

They “prioritize high-value recoverables,” said Mina Ha, an analyst at battery consultancy Rho Motion. “Everything else ends up as waste.”

Getting the system working right would also help Chinese automakers better market their cars overseas. The EU has set mandatory minimum levels of recycled content in electric cars sold there, initially at 16% for cobalt, 85% for lead, 6% for lithium and 6% for nickel. There’s also the obligation to set up an electronic ‘battery passport’ and a QR code by 2027 to verify the source of raw materials, along with separate lithium collection targets for waste batteries.

“Chinese carmakers have access to both a larger and more mature recycling market, and they’re producing vehicles in a market that doesn’t have the same requirements as the EU,” said Hans Eric Melin, managing director at Circular Energy Storage. That means Chinese manufacturers can direct batteries with recycled content to cars for export to Europe, he said.

China’s “main advantage lies in its strong position in battery material production, of which recycling is an integrated process,” Melin said. “That’s what we haven’t really got our head around in the West.”

Source : finance.yahoo.com